Fuseholders

Fuseholders are circuit protection devices used to fix and install fuses and ensure their reliable operation. Their core function is to provide physical support and electrical connection for fuses while facilitating installation, maintenance, and status monitoring.

1. What are the Core Function of Fuseholders?

Circuit Protection: Prevent overcurrent or short circuits from damaging the equipment by stably fixing the fuse.

Installation and Maintenance: Simplify the replacement process of fuses, and some models support quick plug-in or anti-mistaken touch design.

Status Monitoring: High-end products integrate blown fuse indication functions (such as LED or mechanical markings) to facilitate real-time detection of fuse status.

2. What are the Structural Design of Fuseholders?

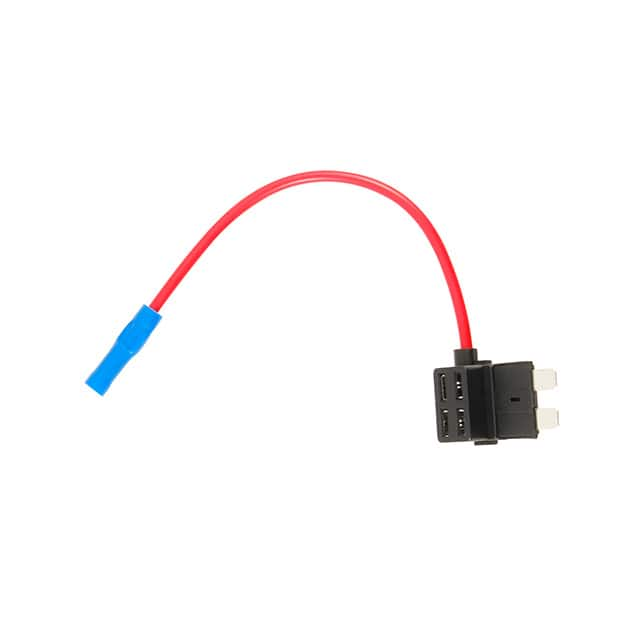

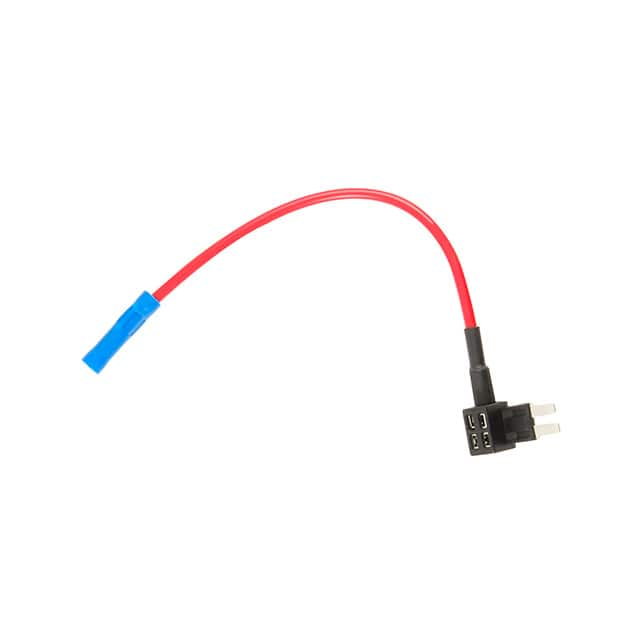

Adaptability: Designed according to fuse size and type, such as 5×20mm, 3AG, etc., supporting micro (PICO®), automotive (Blade-Type), and industrial-grade fuses.

Installation Method: Including panel mounting (Panel Mount), PCB welding (such as HB PCB series) rail fixing, etc., to meet the needs of different scenarios.

Protection Level: Some models are waterproof and dustproof, suitable for harsh environments.

Material: High-temperature resistant and flame-retardant materials (such as UL 94V0 certified engineering plastics) are used.

3. Where are Fuseholders Used?

Industrial Equipment: For example, the ABB E90 series supports photovoltaic systems (1500 VDC) and motor control cabinets, providing short circuit and overload protection.

Automotive Electronics: Manufacturers such as Eaton provide automotive-grade fuse holders to meet the needs of vehicle-mounted circuit protection.

Consumer Electronics: Miniature fuse holders are used for power adapters, smart devices, etc..

4. What are the Technical Parameters of Fuseholders?

Electrical Performance: The withstand voltage range is usually 250V~1500V, and the rated current ranges from 0.5A to hundreds of amperes.

Environmental Adaptability: The operating temperature covers -40℃~85℃, and some models are certified by CE, UL, etc..

5. What are the Main Manufacturers of Fuseholders?

Littelfuse: Covers various types such as Inline and Cartridge, supports PCB installation and waterproof design.

ABB E90 Series: Optimized for high voltage scenarios, equipped with fuse indication and compact structure.

Eaton: Provides full-category solutions for automotive and industrial grades.

The design and application of fuseholders need to be combined with specific circuit requirements, and the appropriate size, installation method, and protection level should be selected to ensure system safety and maintenance convenience.