A Complete Guide to SMD Components

Table Of Contents

An essential component of the electronics industry is Surface Mount Devices (SMD). Miniaturized circuits, sleeker designs, and improved performance have all been made possible by these tiny gadgets. Understanding SMD components is crucial for understanding how electronic circuits function if you work with electronics. Whether they are engineers, enthusiasts, or simply interested in the operation of their commonplace gadgets, anyone with an interest in electronics should read this tutorial.

1. Understanding SMD Components

Electronic parts that are physically affixed to printed circuit boards (PCBs) are known as surface-mount devices. Through-hole technology components (THT), which require that holes be drilled into the PCB to install, have been largely replaced by SMD components. SMD components enable a more efficient and compact design because of their reduced size.

SMD components are essential to the operation of electronic devices. These components are found in almost all electronic devices, such as computers, mobiles, and household appliances. They are primarily used to control the flow in an electrical circuit. However, depending on their specific type, they can perform other tasks.

SMD components offer several advantages compared to traditional through-hole parts. They are lighter and smaller, allowing for smaller electronic devices. They can also be placed on the back and front of a PCB to increase circuit density. This allows for more complex designs. SMD components are installed by automated equipment which lowers production costs and speeds up production.

2. Basic Types SMD Components

Surface Mount Devices (SMDs) are available in many types. Each type has a unique function within an electronic circuit. SMD components are mainly resistors and capacitors.

2.1 Resistors

One of the most popular types of SMD components is resistors. They limit the flow of electric current in a system. Resistance is measured by ohms. SMD resistors have resistance values that range from 1 ohm up to several megaohms.

SMD resistors are available in different types. Every kind is made for a certain need. Thin-film resistors, for example, are renowned for their precision and stability. For precision applications like instrumentation, they are therefore perfect. The resistance values range from 1 ohm up to 3 megaohms with tolerances as low as 0.1%.

However, compared to thin-film resistors, thick-film resistors are less widely used and less expensive. They are employed in general-purpose settings where accuracy is not necessary. Thick-film resistances come in a range of values from 1 ohm up to several gigaohms. Tolerance values are typically between 1% and 5%.

A current sense resistor is another type of SMD resistance that is used to measure electrical current. These resistors are very low resistance, usually less than 1ohm. They produce voltage drops proportional to current flow. After that, the voltage drop is monitored and utilized to determine the current.

Metal foil resistors and wire-wound resistors are also available in high precision and high stability. The application’s requirements determine the type of resistor that is selected.

2.2 Capacitors

Another fundamental SMD component is the capacitor. Like a temporary battery, they store and release energy. Among the many uses for capacitors are energy storage, voltage stabilization, and noise reduction.

Farads are used to express capacitance, which is a measurement of the capacitor’s capacity to hold charge. Most capacitors in electronic circuits, however, have capacitance values that fall in the range of microfarads (μF), Nanofarads (nF), or Picofarads (pF).

There are numerous varieties of SMD capacitors, each having special qualities of its own. The most common SMD capacitor type is ceramic capacitors. These capacitors are cheap, offer a range of capacitances, and can be mounted in either direction. Their capacitance may vary depending on temperature and voltage. This can be a disadvantage for precision applications.

Tantalum capacitors are another type of SMD. These capacitors are more expensive, but offer better stability and higher capacitance than ceramics. Tantalum capacitors’ high capacitance-to-volume ratio makes them common in power supply circuits.

SMDs can also be film capacitors. High levels of accuracy, stability, and dependability are possessed by film capacitors. High-frequency applications like RF circuitry and high-quality audio employ them.

The final kind of capacitor is an electrolytic capacitor. They have a higher capacitance but less stability and accuracy. These capacitors are polarized, and their lifespan is limited when they’re used at high temperatures. Circuits that need a lot of capacitance can use electrolytic capacitors.

The choice of a capacitor depends on the application. Each type has strengths and weaknesses.

2.3 Inductors

Another kind of SMD component that is crucial to electronic circuits is the inductor. They are used to store power in magnetic fields when electric current flows through them. Inductors are used primarily in analog circuits to stabilize current flow and filter out high frequency noise.

During the PCB manufacture of an electronic device, a toroidal inductor and transformer are used.

Inductance is measured in henries. Inductors in electronic circuits typically have values of inductance in the range of microhenries (μH) and nanohenries (nH).

The most prevalent kind of SMD inductor is a wirewound inductor. The most common SMD inductor is the wirewound type. These inductors are wound around a core of magnetic material and offer high inductances. Their inductance can change with frequency, and this is a disadvantage for high-frequency applications.

Multilayer inductors are another type of SMD. Multilayer inductors offer high inductance in a small package. Multiple layers of magnetic material are stacked to create them. They have a lower capacity to handle current compared with wire-wound inductors.

Ferrite-bead inductors are used in electronic circuits to cut down on high-frequency noise. The inductors are created by threading wires through bead material made from ferrite. Ferrite-bead inductors are very resistant to high frequencies. This allows them to filter out high-frequency noise.

The choice of an inductor depends on the requirements of the application. A wire-wound coil inductor, for example, might be selected for a circuit of a power supply due to its ability to handle high currents. A ferrite-bead inductor, on the other hand, might be selected for a circuit of signal processing due to its noise filtering capabilities.

3. Advanced SMD Component Types

Advanced SMD component types include integrated circuits, diodes, and transistors. These components are more complicated than surface mount components. They are employed in many different applications, such as ICs, signal processing, and power control.

3.1 Diodes

Semiconductor devices called diodes permit one direction of current flow while obstructing the other. They can be used for a variety of applications such as voltage regulation, signal processing, rectification, and more.

SMD diodes are available in a variety of types. Each type has its own unique features and applications. In power supply, a popular form of rectifier diode is used to convert AC to DC. Rectifier diodes can handle high currents and withstand reverse voltages.

SMD diodes come in a number of varieties. Their rapid switching rates and low forward voltage drop are well-known. High-frequency applications, including radio frequency (RF) circuits and power supply switching, employ Schottky diodes.

The Zener diode is another kind of SMD. It is employed to control voltage. Beyond a certain voltage, they start to conduct in reverse. They can maintain a constant current across their terminals. They are therefore perfect for voltage-regulating electrical circuits.

LEDs are a type of diode that emits light whenever a current is passed through them. Display panels and indicator lights are only two of the many uses for SMD LEDs.

A triode is a type of electronic vacuum tube that has three electrodes: a plate, a grid, and a filament (cathode). Compared to through-hole triodes, SMD triodes have a number of benefits and are used in many electrical devices.

The choice of a diode depends on the requirements of the application. For instance, a Schottky may be used for high-frequency applications because of its fast switching speed, whereas a rectifier diode may be chosen for a power supply because of its capacity to manage high currents.

3.2 Transistors

Electrical signals can be switched or amplified using semiconductors known as transistors. Transistors are a key component in the current electronics industry. They are used in a wide range of applications, including digital logic and power amplifiers.

There are numerous varieties of SMD transistors. Every variety has special qualities and uses of its own. The bipolar junction transistor is a common type. It can be either PNP or NPN and has two connectors. Applications for BJTs are numerous and include switching and amplification.

Another SMD type is the field-effect transistor. It controls the flow of electricity via a semiconductor. The two main subtypes of FETs are metal-oxide-semiconductor field-effect transistors (MOSFETs) and junction gate field-effect transistors (JFETs). Applications needing low noise and high input impedance usually use JFETs. In contrast, MOSFETs are frequently employed in high-speed switching applications.

MOSFETs have become very popular in electronics because of their fast switching speeds, low power consumption, and high input resistance. MOSFETs come in two varieties: enhancement-mode and depletion-mode. Depletion-mode MOSFETs and enhancement-mode MOSFETs require gate voltages to be turned on.

The choice of a transistor depends on the requirements of your application. A BJT may be selected for a linear amplifying circuit because of its high current gain. However, a MOSFET could be selected for a switching supply due to the high switching speed and lower power consumption.

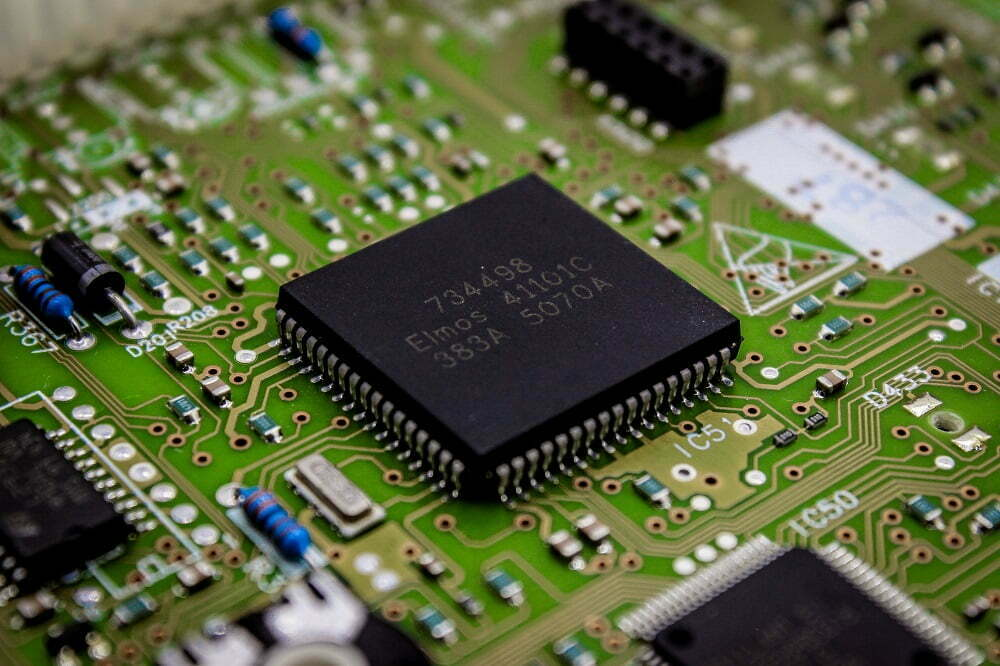

3.3 Integrated Circuits

Electronic components comprising several parts on a single chip, such as resistors, diodes, and transistors, are called integrated circuits. There are numerous uses for ICs. They are found in microprocessors, memory chips, analog-to-digital converters, and power management circuits.

SMD ICs are available in a variety of types, with each type being designed for a particular application. digital IC is a common type, which includes microprocessors and microcontrollers as well as digital signal processors. Digital ICs can be found in many applications that require the processing and manipulation of digital data. Computers, smartphones, and digital audio equipment are a few examples.

Another kind of SMD IC is analog, which includes operational amplifiers, comparators, and voltage regulators. Applications like audio amplifiers, sensors, and power supply that need to process analog signals can make use of analog integrated circuits (ICs). Analog and digital circuitry are combined onto a single chip in mixed-signal IC integrated circuits. These ICs are used for applications that require digital and analog processing, such as radio frequency (RF), data converters, and other circuits.

Power Management ICs are a subset of SMD ICs that are used in electrical devices to distribute and control power. Voltage regulators, battery chargers, and power switches are all part of this group. Applications for power management integrated circuits (ICs) are numerous and include solar power systems, electric cars, computers, and cell phones.

The application’s requirements determine which IC is best. Every type of IC has advantages and disadvantages of its own. A digital IC, for example, might be selected for a motherboard of a computer due to its high-speed processing capabilities. An analog IC, on the other hand, might be selected for an audio amplifier due to its ability to process analog signals.

4. Sizes of SMD components and codes

The size and code of SMD components are important to know when choosing and using them in electronic circuits. SMD components are classified by their size and code, which provides information on the physical dimensions and electrical properties. This enables technicians and engineers to choose the appropriate part for particular uses.

Standard code systems consisting of alphanumeric letters are used to identify SMD components. The code system used varies according to the component type, like resistors or capacitors.

4.1 Resistor sizes and codes

The code of SMD resistors is a three- or four-digit number that indicates the resistance value and the tolerance. The resistance value is represented by the first two or four digits, and the multiplier is indicated by the last digit. A resistor coded “103” would have a resistance of 10 x 10^3 Ohms or 10 Kilohms.

The standard size of SMD resistors is also denoted with a two-digit number, for example, 0402, 0805, 0603 or 0805. The first two numbers represent the resistance’s length in hundredths, and the last two represent its width. A 0603 resistor, for example, measures 0.06 inches long and 0.03 inches wide.

4.2 Capacitor sizes and codes

The three-digit code identifies SMD capacitors and indicates the capacitance rating as well as the voltage rating. The multiplier is the final digit, while the capacitance’s significant values are the first two. A capacitor coded “104” would have a capacitance of 10 x 10^4 picofarads or 100 nanofarads.

SMD capacitors are also available in standard sizes such as 0603 or 0805. The size code is the same as for resistors. The width is represented by the final two digits, whereas the length is represented by the first two.

4.3 Inductor sizes and codes

Inductors SMD are identified by four-digit codes that indicate their inductance and tolerance. The multiplier is the final digit, while the first three represent the inductance’s significant figures. The inductance of inductor code 1002 is 10 x 10^2 Microhenries, or 1 Millihenry.

Inductors are also available in a variety of standard sizes. They look similar to capacitors and resistors. The size code is the same, with the width denoted by the last two integers and the length by the first two.

Understanding the surface mount component codes and sizes is essential for choosing the right components for specific applications and ensuring that electronic circuits work properly.

5. Selection and application of SMD components

It is important to select the right SMD package for an application in order to achieve the best performance and functionality of the electronic circuit. There are a number of things to take into account while selecting SMD components

5.1 Electrical characteristics

An SMD component’s electrical properties, such as its capacitance or inductance, must be suitable for the purpose for which it is designed. A resistor with the right resistance value, for example, is needed to limit current flow in a system. A capacitor with the correct capacitance is needed for energy storage or filtering. To determine the electrical characteristics required for a particular application, it is important to consult datasheets or reference designs.

5.2 Physical Dimensions

The dimensions of SMD components must match the available area on the PCB. The component size must also be compatible with the manufacturing process. Smaller components may need more precise placement or soldering techniques. Standard SMD component dimensions, such as 0603 or 0805, can be used to select components for specific applications.

5.3 Compatible with other components

Electrically and mechanically, SMD components need to be compatible with the other components of the circuit. When linked to a high-voltage source, a capacitor with a higher voltage rating is necessary. Similarly, a resistor of a higher power rating is needed if the component is being used in an application that requires a lot of current. To guarantee consistent performance throughout a broad temperature range, temperature-sensitive applications should also select components with comparable temperature coefficients.

5.4 Examples of SMD Component Selection and Application

- A combination of SMD transistors, resistors, and capacitors can be used to filter and regulate the output voltage in a power supply. Input voltage, output power, load current, and efficiency requirements are taken into consideration when choosing these parts.

- SMD inductors and capacitors can be used to create filters for radio frequency circuits that block certain frequencies while allowing others through. These components are selected based on desired filter characteristics such as center frequency, bandwidth and attenuation.

- SMD resistors and capacitors can be utilized in timing circuits, decoupling capacitors, and pull-up or pull-down resistors in microcontroller-based circuits. These components are selected based on various factors, including the microcontroller’s input and output requirements.

The electrical characteristics, physical dimensions, and compatibility of other components are important factors in selecting the right SMT component for a particular application. This will guarantee the electronic system operates at its peak efficiency.

6. Soldering SMD Components

To ensure that electronic circuits work properly, it is important to use specific techniques and take precautions when handling and soldering SMD components. Surface mount technology (SMT), a process that uses surface mount technology to attach SMD connectors to PCBs, is usually used. Because SMD components are small and sensitive, they are more likely to be damaged.

6.1 Soldering Techniques

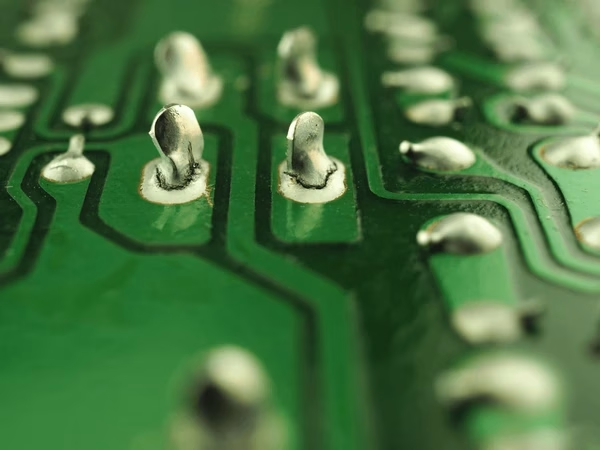

Solder paste is used to solder SMD components. It’s a mixture that contains flux and solder particles. Solder paste is applied using a stencil, syringe or pick-and place machines. The SMD components are placed onto the pads with tweezers. The solder paste is melted by heating the PCB in reflow furnaces. As a result, the component on the PCB forms a solid mechanical and electrical link. Ball Grid Array components (BGAs) are more difficult to solder or desolder as they are on the back of the package.

When soldering SMD parts, there are several important factors to take into consideration:

- Quality of solder paste: Solder paste must have the correct viscosity, metal content, and consistency to adhere to PCB pads.

- Stencil Design: A stencil must be designed so that the solder substrate is evenly distributed on each pad. This will ensure a good connection, without solder bridges and insufficient solder joints.

- Reflow Profile: Program the reflow oven with an appropriate temperature profile that includes preheating and soaking stages, as well as reflowing, cooling, and reflowing. The solder paste will melt and form a strong joint without damaging either the PCB or the component.

- Alignment of components: SMD components must be placed accurately on the PCB pads in order to ensure electrical and proper alignment.

QFP packages can be used to package high pin count SMD integrated components, such as memory chips, microprocessors, and field-programmable gates arrays.

6.2 Handling precautions

To avoid damage and to ensure the reliability and safety of the electronic circuit, it is important to handle SMD components with care. The following should be taken into account when handling SMD packages :

- Electrostatic Discharge (ESD) Protection : Transistors and integrated circuits (ICs) are among the many SMD components that are vulnerable to electrostatic discharge. This may cause irreversible harm. It’s crucial to employ ESD-safe instruments like tweezers, workstations, and wrist straps when working with SMD components.

- Stress from Mechanical Excessive mechanical forces, including twisting or bending, might harm SMD components. When handling and placing SMD components, It’s important to avoid using too much force.

- Temperature controlSMD components are sensitive to humidity and temperature, and this can impact their electrical characteristics. It is crucial to handle and store SMD components in a regulated environment to guarantee long-term functioning.

It is possible to integrate SMD or SMT electronic components into circuits by using the correct soldering technique and handling precautions. This will ensure optimal performance and reliability.

7. Summary

Anyone involved in electronics must understand the different types of SMD components, their functions, and applications. Every component is essential to the functioning of electronic circuits, ranging from SOT components like resistors and capacitors to sophisticated components like integrated circuits, transistors, and diodes. For electronics to operate at their peak efficiency and dependability, these components must be carefully chosen, handled, and soldered.

8.FAQS

Q: What are SMD components?

A: SMD, or Surface Mount Device, components are electronic components designed to be directly mounted onto the surface of a printed circuit board (PCB), rather than being inserted through holes as with traditional through-hole components.

Q: What is the difference between SMT and SMD?

A: SMT is the overall process of mounting and soldering electronic components directly onto the surface of a printed circuit board (PCB). SMD refers to the components themselves that are designed for this surface mounting process.

Q: What temperature is needed to remove SMD components?

A: 350 to 380 degrees centigrade

Q: How do I identify SMD components?

A: Utilize reference charts, datasheets, and online resources to help identify distinctive codes, dimensions, and polarity markings.

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto

Latest Blog

Table Of Contents

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto