A Detailed Overview of Copper Clad Laminate

Table Of Contents

1. What is Copper Clad Laminate?

Copper Clad Laminate (abbreviated CCL) is a base material for PCBs. A copper-clad panel is made by laminating glass fiber or wood paper with copper on one or both sides after the material has been soaked in resin.

2. How are CCLs classified?

CCLs are classified according to different standards.

- We have rigid CCL (FR-4 CEM-1, etc.) based on the mechanical rigidity of CCL. Flex CCL. Flex PCBs rely on flex and rigid CCLs.

- We have organic resin CCL in FR-4 (FR-4), CEM-3 (CEM-3), etc., metal-base CCL, ceramic-base CCL, etc.

- We have two types of CCL based on thickness. The thickness of the former must be at least 0.5mm, while that of the latter may be less than 0.5mm. The CCL thickness does not account for copper foil thickness.

- We have glass fiber cloth CCL, paper CCL, and compound CCL.

- We have two types of CCL based on the insulation resin used: Phenolic (FR-1,XPC) and epoxy CCL.

3. What makes a good CCL?

CCLs can only meet performance requirements when they are able to cater to the following:

- Appearance. Unexpected elements in the production process, like dents or scratches, resin points, wrinkles, pinholes, bubbles, etc., might have an impact on copper foil. These issues will all result in a poor CCL and, eventually, a PCB.A CCL that is excellent should have a flat, smooth appearance.

- Size. As CCLs are the base material for PCBboards, they must conform to the size requirements of PCBs. The size of CCLs is determined by several parameters, including length, width, and diagonal deviation.

- Electrical performance. It is essential that a PCB achieves this mission. Therefore, any factor affecting the electric performance of the board must be designed carefully. This includes dielectric constant, dielectric loss tangent, volume resistance, surface resistivity, insulation resistance, and arc resistance.

- Performance. The physical performance of CCLs is determined by dimensional stability (PS), peel strength (PS), bend strength, heat resistance, thermal stress (Td, T260, T288, and T300), punching qualities, etc.

- Chemical Performance. The chemical performance of CCLs must meet requirements such as flammability and chemical resistance to reagents, Tg, Z axis coefficient thermal expansion (Z CTE), dimensional stabilities, etc.

- Environmental performance. It must meet the requirements of water absorption, etc.

PCB Fab Houses should perform CCL quality judgment. AssemblePCB, for instance, uses IPC-4101C for manufacturing standards and IPC-TM-655 for CCL tests. CCLs are therefore qualified as PCB substrates when they meet these standards.

4. Prepreg: What is it?

Prepreg is the reinforcing material found within a CCL. It is baked and composed of glass fiber. Some people call it a bonding sheet, and it is composed of epoxy resin, DMF cloth, 2MI, Acetone, etc.

Classification of prepreg. There are many classification standards for prepreg.

1). Based on glass fibre cloth: 106; 1080; 2112; 2116. 1500 and 7628.

2). Based on the resin used and its performance, POLYCLAD Turbo254/226, ISOLAFR402/FR406,ITEQIT180, Sheng YiS1141-140/170

Resin Classification

1)Phenolic resin

2)Epoxy resin

3)Polyimide resin

4) Polytetrafluorethelene resin (PTFE or TEFLON resin)

5) Bismaleimide triazine (BT)

Glass Fiber is characterized by the following attributes:

1)High intensity

2) Fire and heat resistance

3) Humidity Resistance

4) Excellent insulation capabilities

Factors that affect the quality of prepreg. A high-quality prepreg will lead to a high-quality PCB, and then CCLs. AssemblePCB is very concerned with the quality of prepreg, and tests and controls it in terms of resin, gel time, and resin fluidity.

Select prereg according to cost. Glass fiber cloth is the main factor in the high cost of prepreg. In general, prepreg costs are directly correlated with the thickness and quality of the glass fiber cloth. The cost of prepreg increases as the thickness of the cloth decreases. Prepreg 1080 is cheaper than prepreg 1112 because it is rarely used.

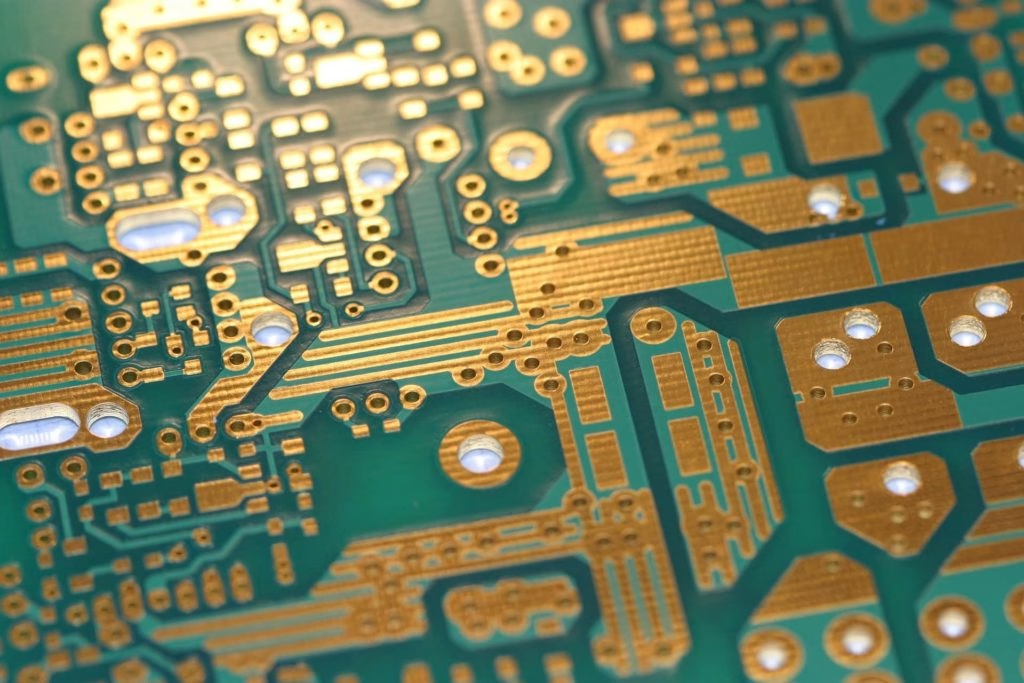

5. What Is Copper Foil?

The following table summarizes copper foil by technology and class.

| Class | Type | Name | Code |

| 1 | E | Standard electrodeposited | STD-Type E |

| 2 | E | High ductility electrodeposited | HD-Type E |

| 3 | E | High temperature elongation electrodeposited | HTE Type E |

| 4 | F | Annealed electrodeposited | ANN-Type E |

| 5 | W | As rolled-Wrought | AR Type W |

| 6 | W | Light cold rolled-Wrought | LCR Type W |

| 7 | W | Anneal-Wrought | ANN Type W |

| 8 | W | As rolled-Wrought low-temperature annealable | ARLT Type W |

Copper foil is classified according to its performance. Standard copper foil is used for FR-4 or paper base boards, HTE is used for multilayer PCBs in order to feed back the split ring issue, and low profile copper foil is also applied to multilayer PCBs.

6. A New Trend in CCL

To meet the RoHS regulations (restriction of hazardous substances), CCLs are subjected to higher standards in terms of reliability and heat resistance. The following two aspects are modified:

Halogen-free CCL. This refers to CCLs with a chlorine (Cl), bromine (Br), and overall content that is not more than 1500ppm. The following table summarizes the performance comparison between ordinary FR-4 and halogen-free FR-4 CCLs.

| Item | Halogen-free CCLs | FR-4 CCLs |

| Flammability | V-0 | V-0 |

| Peel strength | Bad | Good |

| Heat performance | Good | Bad |

| Thermal decomposition | >320°C | 310°C |

| Size stability | Excellent | Bad |

| T260 | >30min | 10min |

| Bending strength | Bad | Good |

Lead-free CCL. This type of copper-clad PCB does not use lead-free solder for surface mounting. Brominated epoxy resin is the primary resin used in lead-free CCLs. The RoHS states that six chemicals, including PBDE and PBB, are no longer utilized in CCLs. Ordinary FR-4 CCLs adopt the DICY curing system (with dicyandiamide as the curing agent), while lead-free CCLs adopt the PN curing system (with phenol-formaldehyde resin as the curing agent).

| Item | DICY | PN |

| Peel strength | Good | Bad |

| Thermal performance | Bad | Good |

| CAF resistance | Bad | Good |

| Thermal decomposition temperature | 310°C | >320°C |

| Water absorption resistance | Bad | Good |

| T260 | 10min | >30min |

| Bending strength | Good | Bad |

The PCB and CCL industry has accepted standards for peel strength of halogen-free CCLs as well as lead-free CCLs.

| Specification | IPC Standard | Attributes | ||

| 1 b/in | Kg/cm | LF/HF typical value | ||

| 12μm | / | >5 | >0.9 | / |

| 18μm | / | >6 | >1.05 | 1.15Kg/cm |

| 35μm | >1.05N/mm | >8 | >1.4 | 1.5Kg/cm |

| 70μm | / | >11 | >2.0 | / |

Backed by over 12 years of dedicated efforts and industry experience, AssemblePCB has been making active contributions to the growth and prosperity of the PCB sector. It is well-prepared to deliver high-quality, eco-friendly PCBs—along with the corresponding types of copper clad laminates (CCLs)—at competitive price points.

AssemblePCB, one of the top PCB manufacturers in the world, offers excellent, environmentally friendly PCBs. Join together with AssemblePCB for top-notch PCB solutions. Get a free quote right now!

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto

Latest Blog

Table Of Contents

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto