HASL vs ENIG: Choosing the Best Surface Finish for Your PCB

Table Of Contents

Introduction

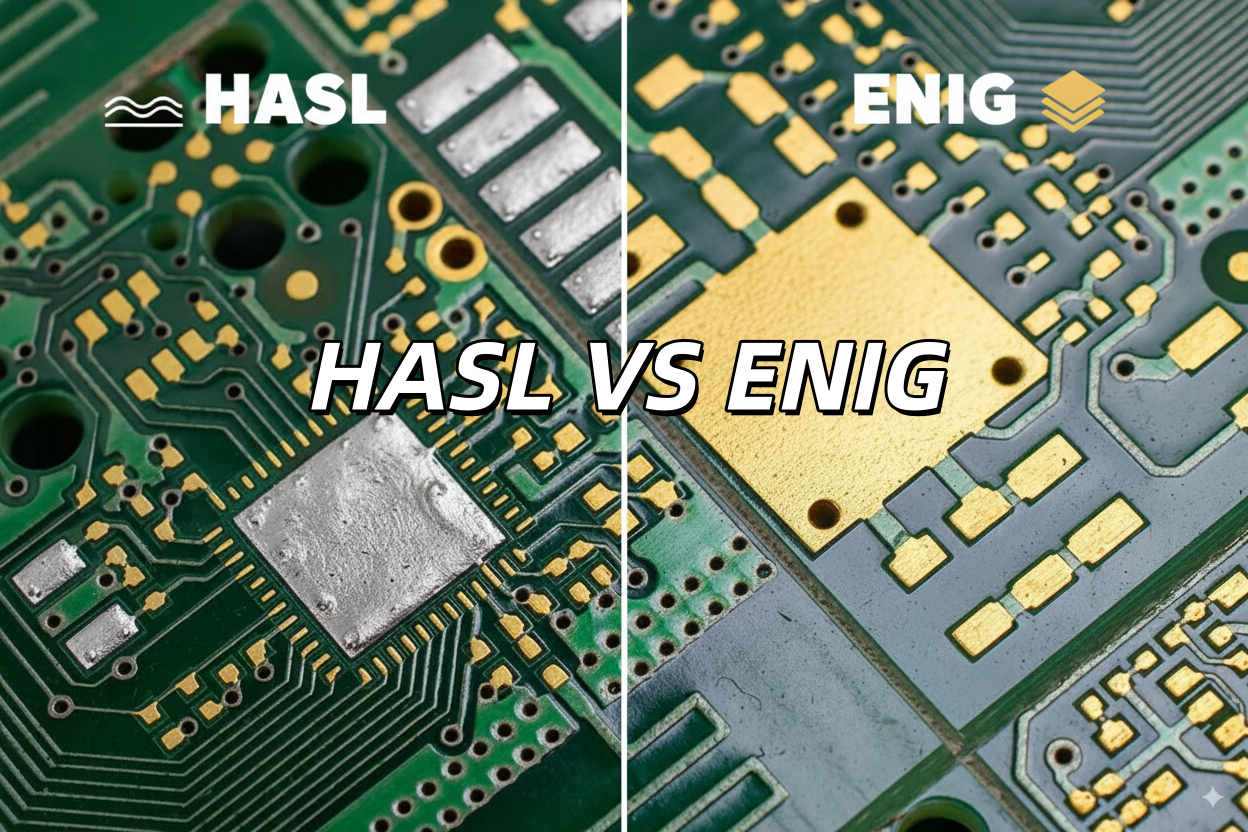

Surface finishes are crucial in PCB production. They guarantee peak performance and shield exposed copper traces. These finishes are a barrier to oxidation, and they facilitate soldering connections that are reliable. They have a direct impact on the longevity and performance of electronic gadgets. Two common surface finishes have arisen as a result of their distinct benefits and drawbacks: Electroless Nickel Immersion Gold (ENIG) and Hot Air Solder Level (HASL).

The HASL method involves submerging the PCB into molten silver, followed by a step of hot air drying. In contrast, ENIG entails putting a small coating of gold after a nickel layer. A careful choice between HASL and ENIG can have a significant impact on the solderability, shelf-life, and overall reliability of a Printed Circuit Board.

AssemblePCB provides expert services for PCBA. This covers the application and choice of various surface finishes, such as Electroless Nickel Infusion Gold (ENIG), Hot Air Solder Leveling (HASL), or advice on which finish is ideal.

1. HASL VS ENIG–HALL

1.1 Definition

Hot Air Solder Leveling (HASL) is commonly abbreviated as ‘HASL’. This is a surface finish that’s used in the printed circuit board industry to provide a long shelf life as well as a reliable solder joint. hot air soldering leveling makes it easier to solder a component. Initially, HASL is applied as a finish to improve solderability. It also covers exposed copper circuitry.

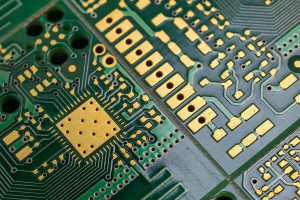

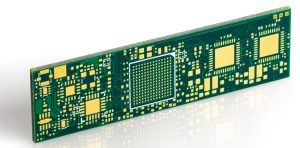

HASL VS ENIG – HASL

1.2 HASL Finished

The HASL has been a popular surface finish for many years, with advantages such as low cost, repairability, and availability.

As we have discussed, HASL offers a surface finish that is solderable and has a long shelf life. The printed circuit boards are submerged in a container of molten metal solder to coat the copper surfaces during the HASL process.

Then, using the hot air knife to level the circuit board and remove excess solder. The printed circuit boards must be covered or the copper will oxidize, making the board useless.

Copper finishes are found on the printed board. This finish creates an interface between the printed board and the component.

2. HASL VS ENIG–ENIG

2.1 Definition

The ENIG acronym stands for Electroless Nickel Infusion Gold. Because it is composed of electroless nickel plating with a thin coating of immersion gold, the ENIG gets its name. Hot air solder leveling is a surface finishing used in the printed circuit boards industry. It has consistently gained market share due to its flexibility in different component assembly processes.

HASL VS ENIG – ENIG

2.2 ENIG Finish

The two-layer finish is a metallic coating consisting of an electroless layer that is coated with immersion gold. During storage, the nickel serves as a barrier for the copper, and the immersion gold shields it. ENIG has become one of the most popular surface treatments in the printed circuit board industry due to its advantages.

2.3 ENIG Plating

In the early stages, ENIG plating is not reliable. This type of leaf has reliability problems. Electroless immersion nickel-gold is not uniformly wetted, unlike hot air solder leveling. The copper pads have been separated from the finish as a result. The nickel ions in the reducing agent must be replaced to ensure the coating is at the right temperature and concentration.

3. Advantages and Disadvantages of HASL and ENIG

We have already discussed the two finishes. In essence, hot air solder leveling (HASL) possesses certain distinct advantages over electroless nickel immersion gold (ENIG), and the reverse is also true. In this, section we will describe each surface finish and its advantages and disadvantages. Note that there is no surface finish without its disadvantages. Therefore, choosing a surface finish depends on the application.

3.1 Advantages of the HASL

Hot air solder uniform process type HASL is widely used on the surface of printed circuit boards in the PCB Industry. Its use has many advantages:

- The printed circuit board can be exposed to temperatures as high as 265°C. Before any components are attached to the printed circuit board, any potential issues can be found by exposing it to this degree of weather.

- It is easy to operate the hot air solder leveling.

- This is a surface finish which is affordable.

- hot air solder leveling has a reputation for offering a long-lasting storage life.

- It is widely available. It is a great alternative to other surface finishes.

- A flawless wetting during the soldering or connecting of components.

- The components must be wetted perfectly before joining or soldering.

- Visual inspection is possible for this type of surface finish.

Multi-Layer PCB with HASL

3.1.2 Disadvantages of the HASL

According to one viewpoint, every benefit is always connected to a disadvantage. Every kind of surface finish has advantages and disadvantages. Among the flaws in the hot air solder leveling that have been found are:

- Because hot air solder leveling involves uneven surfaces, this kind of surface finish is not appropriate for Surface-mount technology (SMT).

- In keeping with the first point, it is not eligible for fine pitch. In order to improve flatness, horizontal levelers are necessary.

- HASL has some limitations that make it unsuitable for manufacturing when it comes to boards that are also thick or thin.

- Due to the high temperatures involved in their production, printed circuit boards can suffer from some disadvantages.

- unable to tolerate the plated holes’ strict tolerance.

- Line binding is not suitable for hot air soldering leveling.

- Using this surface finish at high temperatures may cause the plated through holes to break.

3.2 Advantages of the ENIG

- The electroless nickel immersion gold provides a flat surface in contrast to the hot air solder leveling method.

- This type of surface finish is well-suited for plated through holes.

- Similar to hot air solder leveling, it has a long shelf life.

- No lead

- This surface finish can be used as the bottom metal of cob wire.

- ENIG exhibits exceptional electrical conductivity.

- Electroless nickel immersion gold (ENIG) is well recognized for its resistance to oxidation.

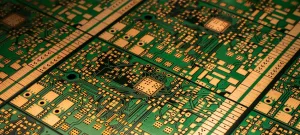

Electroless Nickel Immersion Gold Surface Finish

3.2.1 Disadvantages of the ENIG

- The cost is a major issue.

- In contrast to hot air solder leveling (HASL), electroless nickel immersion gold (ENIG) is not amenable to rework.

- Signal loss is a problem with electroless nickel immersion gold

- ENIG is more complex than HASL.

- ENIG’s low strength makes it vulnerable to the black pad

4. Other Surface Finish Process

4.1 OSP

OSP stands for Organic Solderability Preservative. Also known as anti-tarnish, the organic solderability preserver is an organic preservative. This surface finish protects copper’s surface from oxidation. This is achieved by applying a thin layer of material to the copper surface using a specific process. This finish is made with organic compounds, usually water-based, that bond to the copper. The result is a metallic and organic layer that protects the copper before soldering.

Organic Solderability Preservative

4.1.1 Advantages of OSP

- In contrast to hot air solder leveling (HASL), organic soldering preservatives deliver a flat surface.

- The process involved in organic soldering preservatives is comparatively straightforward.

- It allows for rework.

- It guarantees an extremely smooth surface.

- It serves as an excellent option for surface mount technology (SMT).

- It is well-suited for lead-free soldering processes.

- This type of finish is economical.

- It ranks as a top choice for horizontal production lines.

- It presents no hazard to the environment.

- It can be combined with other surface finish types on a single panel.

4.1.2 Disadvantages of OSP

- After multiple soldering cycles, the film becomes damaged.

- It is unsuitable for electrical measurements.

- It is incompatible with plated through holes.

- Unlike the aforementioned surface finishes, OSP has a short storage or shelf life.

- It demands careful handling.

- Its thickness cannot be measured.

- It has strict storage condition requirements.

4.2 HARD ELECTROLYTIC GOLD

This type is composed of a gold sheet that has been coated with a nickel barrier coat. This type is only known as “hard-gold.” The majority of its applications are commonly found in keypads, connector fingers, and other areas. Its ability to vary in thickness is one of its main advantages over electroless nickel immersion (ENIG). Hard gold is generally expensive and has a low soldering capability.

Printed Circuit Board (PCB) with GOLD

4.2.1 Advantages of hard gold

- It is a durable and reliable surface.

- Storage life of hard gold is good

- No lead

4.2.2 Disadvantages of hard gold

- This surface finish type is expensive.

- It calls for extra processing steps.

- Etching damage may lead to flaking.

- Hard gold utilizes resist materials.

- It has soldering limitations: it cannot be soldered beyond 17µin.

- Aside from finger areas, this finish does not encapsulate trace sidewalls.

4.3 IMMERSION TIN

This is a metallic finish applied directly to the metal on the printed circuit boards. It is a metallic finish that prevents oxidation and has a long storage life. We’ll take a look at some of the benefits and drawbacks associated with immersion tin.

4.3.1 Advantages of the immersion in

- The immersion tin can be reworked

- Press-fit pins can be inserted easily with this product.

- The immersion tin is free of lead

- It provides a flat surface

4.3.2 Disadvantages of the immersion in

- It is not an appropriate option for assembly processes.

- Measuring its thickness is somewhat unfeasible.

- Uncovered tin tends to corrode during the final assembly stage.

- This method utilizes agents or substances with carcinogenic properties.

- It tends to incur processing damage rapidly.

4.4 IMMERSION SILVER

Immersion silver has pros and cons when compared with other surface finishes. In some cases, it’s considered to be a superior surface finish.

4.4.1 Benefits of Immersion Silver

- The associated process is straightforward.

- Immersion silver provides a flat surface.

- Immersion silver stands as a top choice for high-quality traces.

- It is cost-effective.

4.4.2 Disadvantages of immersion silver

- There may be some micro-hole problems

- The water can easily be polluted

4.5 NICKEL PALLADIUM (ENEPIG)

From a historical perspective, ENEPIG is not a particularly long-established surface finish process within the PCB industry. Typically, ENEPIG is widely used in the semiconductor sector, and it is also applied to the combination of aluminum and gold.

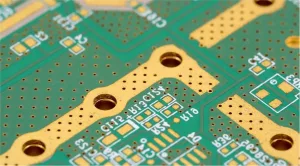

Printed Circuit Board PCB with ENEPIG

4.5.1 Advantages of ENEPIG

- Unlike electroless nickel immersion gold (ENIG), it does not have the black plate issue—meaning there is no nickel corrosion.

- It is an excellent option for lead-free soldering processes.

- ENEPIG boasts a favorable shelf life.

- It is an ideal choice for gold wire bonding.

- It is more cost-effective compared to electroless nickel immersion gold (ENIG).

- It is suitable for a wide range of surface finishes.

4.5.2 Disadvantages to ENEPIG

- Its function is complex, unlike some of the other processes that were mentioned.

- This type of process is still relatively new and has not been well established.

5. Conclusion

Merge Your Plans

While several options have been discussed, the cost of each has not been excluded from consideration. One aspect involves planning to use a surface finish, and another entails carefully selecting the appropriate type that is perfectly suited to your project. For your benefit, it is advisable to assess your project first before determining which surface finish to adopt. If you are working with a limited budget, opting for a surface finish like hot air solder leveling (HASL) is recommended; however, if you choose HASL, you must keep in mind that it is not suitable for RoHS-compliant products.

It’s time

We’ve shown you some common surface finishes, along with the benefits and drawbacks of each. We can guide you to the end of this project, which we have begun. We are available 24/7 to help you. Contact us today! We’d love to hear from you. You can also request a quote, and please do not hesitate to send us any questions or concerns.

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto

Latest Blog

Table Of Contents

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto