Comprehensive Introduction to PCB Surface Finish Types

Table Of Contents

The PCB is the cornerstone of the electronics sector. In many electronic gadgets, it is a necessary component. When making a PCB, the smoothness of its surface is a crucial consideration. The performance, longevity, and regulatory compliance of a board can all be greatly improved by choosing the appropriate coating.

The various types of PCB surface finish will be covered in great detail in this blog. Additionally, you will learn how to choose the best finish for your particular PCB requirements.

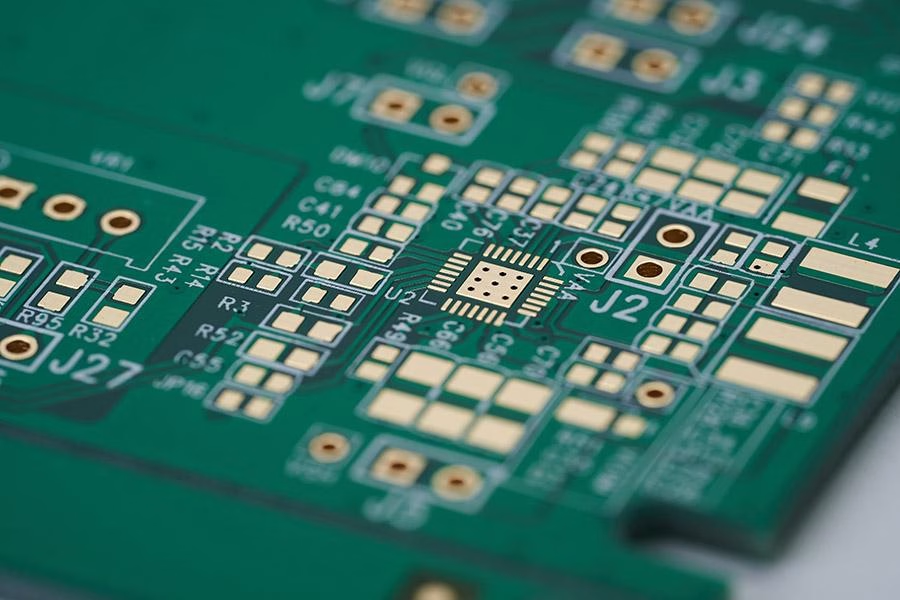

1.The Definition of Surface Finishing on PCBs

Learn a bit about the surface finishes of PCBs.

In essence, a PCB surface finish is a protective layer applied to the copper trace of PCBs. It can increase PCB reliability and longevity. Surface finish promotes solder joints that are strong, which allows for reliable soldering.

Each type of finish is unique. This makes PCBs more suitable for specific applications. Most surface finishes work well with fine-pitch parts. These finishes can also prevent problems like solder mask shifting or tombstoning.

different pcb surface finish

2.There are different types of PCB surface finishes.

Understanding the importance of surface finish on your PCB. The best option for your project can then be selected. Each has unique benefits and drawbacks.

The various surface finish types will now be covered in detail.

2.1 Hot Air Solder Level (HASL)

The most widely used and reasonably priced surface finish is HASL. The procedure is fairly easy. Dip the PCB into the metal that has melted. The copper is then soldered to be removed from the tank. The PCB surface is leveled using hot-air knives. The surface is now solderable.

HASL can be used with both large components and SMTs. SMTs that are too small will not perform as they should. Fine Pitch Technology and Fine Pitch Technology are not compatible. Process temperatures can range between 260 and 270 degrees. High temperatures can damage circuit boards. This alloy contains a high amount of lead. Lead in the alloy is carcinogenic. It’s usually dipped into tin-lead. This means it’s not RoHS compliant.

2 .2 Lead-Free HASL

Lead-free HASL has the same properties as conventional HASL, but does not contain any lead. There are numerous applications for it. It is RoHS-compliant. It has all the advantages of traditional HASL.

2.3 Organic Soderability Preservatives(OSP)

OSP is the process used to finish printed boards with copper foil. It meets the RoHS directive. OSP stands for organic solvents preservatives.

OSP is resistant to heat shock, moisture, and oxidation. Under normal conditions, it can only protect copper surfaces from further corrosion. In the high-temperature weld process, it is necessary to remove the protective film quickly and easily by using flux. It is an easy way to quickly and efficiently form a solid connection by combining the clean copper surface with the molten metal.

hasl vs lead-free hasl vs osp

This surface finish is a water-based finish that protects the copper until soldering. This coating prolongs the life span of copper by preventing oxidation. This coating is less durable on organic surfaces and more sensitive. This product has a very short lifespan.

OSP is a cost-effective surface finish. It is an easy operation that takes very little time. The coating does not affect the size of holes on the PCB. It has a flat surface and a good finish. It is perfect for areas where PCBs are handled with caution. It is durable.

2.4 Immersion Tin

Immersion Tin is a surface finish that does not contain any lead. This surface finish can be used for small parts. This surface finish is ideal for Fine Pitch Technology due to its flat and thin finish.

PCBs with a surface finish are not only affordable, but they also have their disadvantages. Tin can react and shorten the shelf life of PCBs by reacting with their copper layers. It is also important to use it as soon as possible because it is easily tarnished. It is very sensitive. You will see tin whiskers after a few weeks. All current solders are tin-based, so the tin can be used with any solder.

2.5 Immersion Silver

The price of immersion silver surface finish is reasonable. The finish is flat. Silver plating protects the copper from oxidation. The silver layer, although thin, is very conductive. The silver layer does not affect the size of the hole, which is perfect for Fine Pitch Technology.

This type of finish can tarnish easily. The silver layer tarnishes when exposed to air. Anti-tarnish packaging is used to prevent this. After removing it from the package, silver is extremely sensitive and must be soldered. Immersion silver has a moderate durability. It is also affordable and compliant with RoHS standards.

immersion tin vs immersion silver

Immersion silver is a process that falls between electroless Nickel and Immersion Gold and OSP. This is an easy and quick process. Even if the PCB is exposed to humidity or heat, it can still be soldered well. However, the PCB’s luster will fade. Immersion silver does not have the same physical strength as electroless Nickel/immersion Gold because it doesn’t contain nickel.

2.6 Plated old

Hard Gold is another name for Plated Gold. Surface finish is expensive because it adds a layer of gold to the PCB. The PCB is coated with a gold layer by electroplating. The circuit board is strengthened by the gold layer, which is tightly bonded. Gold is a superior conductor and offers a high-quality electrical performance. The gold finish also has a commendable resistance to oxidation. PCBs are ideal for this finish, since they can withstand high wear. The gold surface finish can last a long while.

This type of finish is expensive due to the extra processing needed. The thickness of the gold affects the price. As the thickness of the gold immersion rises, so does the cost. Processing surface finish is challenging. It is a rare material because of its high cost, but it has a great surface finish. Hard gold is not solderable.

2.7Electroless nickel immersion gold (ENIG)

ENIG is the most common ENIG due to its RoHS compliance and properties. The copper is coated with nickel and then a thin gold layer is placed on top. The nickel layer is soldered to the components and the thin layer of gold protects them until soldering has been completed. ENIG produces a PCB with a pure top gold layer. It is softer than gold electroplated. It is commonly known as “soft plating”.

plated gold vs enig

ENIG is durable and has a long shelf life. Due to the two layers, it is expensive. It’s thin, flat and has a smooth finish. This allows it to be used on smaller components. The black pad syndrome is ENIG’s sole problem. This is caused by the accumulation of phosphorus between the gold and the nickel layers.

2.8 Electroless nickel palladium immersion gold (ENEPIG)

ENEPIG’s surface finish prevents air reactions and corrosion. Its best feature is its long shelf life. This type of surface finish is made up of three layers of gold, palladium and nickel. They provide long-lasting performance when combined.

Unlike ENIG, there is no “black-pad” syndrome. RoHS compliant and lead-free. Its high price and complicated processing are the main concerns when using this product.

You can utilize more mixed processes in addition to the ones mentioned above. For optimal results, it is advised to combine two or three surface finishes. PCBs can have multiple finishes. ENIG+ OSP or ENIG+HASL is the most common surface finish.

The benefits and drawbacks of PCB surfaces are contrasted in this table.

| Type | Advantages | Disadvantages |

| HASL | Popular, cost-effective, strong durability. | Lead causes cancer, uneven surface and heat. |

| Lead–free HASL | High surface flatness, RoHS compliant and excellent durability. | Uneven surface requires higher temperatures. |

| OSP | Inexpensive, flat surface, lead-free. | Limited corrosion resistance and limited shelf life. |

| Immersion Tin | Lead-free, excellent solderability. Smooth surface. | Tin whiskers are easily oxidized and damaged. |

| Immersion Silver | Flat, affordable, eco-friendly, good solderability, |

Short shelf life and easy to tarnish. Limited tolerance for harsh environments. |

| Gold | Excellent finish, good electrical performance, durability. | Complex, expensive, and difficult to solder. |

| ENIG | Flat surface with high corrosion resistance. | Complex process, high cost, “black pad” defect risk, signal loss. |

| ENEPIG | The flatness is excellent, and the pads are free of black pads. RoHS compliant. | Processing restrictions are expensive and restrictive. |

| Mixed Surface finish | Performance optimization | – |

3.The importance of PCB surface finish

PCBs are not complete without a PCB’s surface finish. Without it, copper surfaces that are exposed to air and moisture will quickly oxidize. PCBs can fail in a catastrophic way. Surface finish of PCBs also affects reliability, performance and lifespan.

It serves as a barrier to protect soldered components from exposed copper traces.

3.1 Protection from Corrosion

PCBs are susceptible to corrosion in humid or harsh environments. PCBs are protected by the surface finish. This can stop copper traces from oxidizing with time. Maintaining electrical integrity is vital.

3.2 Environmental Resilience

PCBs are susceptible to degradation by factors in the environment, such as humidity, temperature fluctuations and chemicals. You can increase the reliability of a product by selecting the right surface finish for each application.

3.3 Component Compatibility

This ensures the PCB surface level. It is necessary for fine-pitch components to be placed precisely. This increases the production and improves electrical conductivity.

3.4 Reflow Cycle Durability

Finishes should be able to withstand repeated exposure to heat for applications that need multiple reflow-soldering cycles. The reflow resistance of ENIG (Electroless Nickel Immersion Gold) is well known.

3.5 Lead-Free Compliance

Lead-free finishes are required by strict regulations to reduce the quantity of hazardous substances. An environmentally friendly choice is lead-free HASL or ENIG.

3.6 Connector Lifespan

In applications where connectors are regularly plugged in and disconnected, finish is essential. Gold hard or soft finishes provide premium durability and reliable connections.

3.7 Solderability

The term “solderability” refers to the surface’s ability to form strong and reliable connections during assembly. The finish of the surface has an impact on the soldering. The finish of the surface directly affects assembly efficiency and joint strengths.

3.8 Surface Flatness

A uniform, smooth surface is essential for fine-pitch and high-quality soldering. Surface flatness improves electrical performance and simplifies production.

8 Points of The Importance of PCB Surface Finish

4.The Key Factors in Selecting a PCB Surface Finish

When selecting a surface finish for your PCB, take into account the following factors:

4.1Cost Limitations

Cost influences your decision. Prioritize it. Hard gold is more durable but also more expensive. Consumers on a budget will find immersion silver to be a great choice. ENIG offers high performance, but at a pricey price. OSP has fewer features and is more affordable.

4.2Requirements for Lifespan

Some surface finishes last longer than others. ENIG and immersion Gold are more resistant to thermal cycling, environmental stress and wear than other finishes.

4.3 Environmental Compliance

Make sure that the finish meets industry standards. Lead-containing finishes, such as HASL, are not suitable for RoHS compliance.

4.4 Signal Integrity

In high-speed/high-frequency PCB design, we must first consider surface flatness and low signal loss. This time, immersion silver or gold is the best option.

4.5 Solderability

Reliable soldering is crucial for a high-quality assembly. HASL or ENIG are typically the best solder joints.

4.6 Storage Duration

Choose surface finishes that have a long shelf life, such as ENIG, immersion silver, or other surfaces with a high shelf life.

4.7 Specific Needs

Consider the PCB’s purpose. Components with fine pitches that need ultra-flat surfaces are best suited for immersion tin and immersion silver.

The finishes are different in each field. High-frequency applications benefit from finishes that minimize signal loss. Flat surfaces are important. Then, immersion silver will be the first choice. Hard gold is an excellent choice for connectors, which are often mated due to its high wear-resistance.

4.8 Operating Environment

Surface finish is determined by the application scenario for PCB. Before choosing, you should consider the extremes of temperature, humidity and the exposure to chemicals or gases. For harsh environments, you should select a finish with a high level of durability like ENIG or Hard Gold.

5.PCB Surface Finish FAQs

1)Which is better: ENIG or HASL?

ENIG is superior to HASL for fine-pitch components, but it costs more.

2)How do RoHS and REACH differ?

RoHS limits the use of hazardous materials in electronic devices.

REACH is an international regulatory system for chemicals that protects the environment and human health.

3)What is the best finish on PCBs for soldering?

HASL or ENIG is usually the best solderable material for strong joints.

4)What is the new technology in surface finishing?

Nano-coatings are a relatively new technology. They enhance PCB performance in modern applications.

5)What types of surface finishes are used for PCBs?

These include HASL (Halogenated Silver), ENIG (Intrusion Tin), Immersion Silver and OSP.

6)What’s the difference between ENIG and Plated Gold?

Plated gold is ideal for mechanical applications that require high wear resistance and where hardness is important. ENIG is perfect for high-reliability electronic components and fine-pitch soldering where flatness and solderability are important.

7)How should I handle and store PCBs with surface finishes?

You should store them at a specified temperature/humidity. Use anti-static packaging. Avoid UV exposure and follow the shelf-life guidelines provided by the manufacturer.

6.Surface Finishing in Orinew

Orinew Surface Finishing One of the top companies in China’s PCB manufacturing sector is Orinew. We follow stringent RoHS guidelines. We manufacture high-quality PCBs.

We provide a range of surface finishes that can be tailored to our customers’ unique requirements. The cost of PCBs and PCBA assemblies is competitive.

Do you’d like to know more? If you have any questions, please contact us.

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto

Latest Blog

Table Of Contents

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto