Complete Guide to SMD LEDs with Built-in ICs: Types, Applications, and Advantages

Table Of Contents

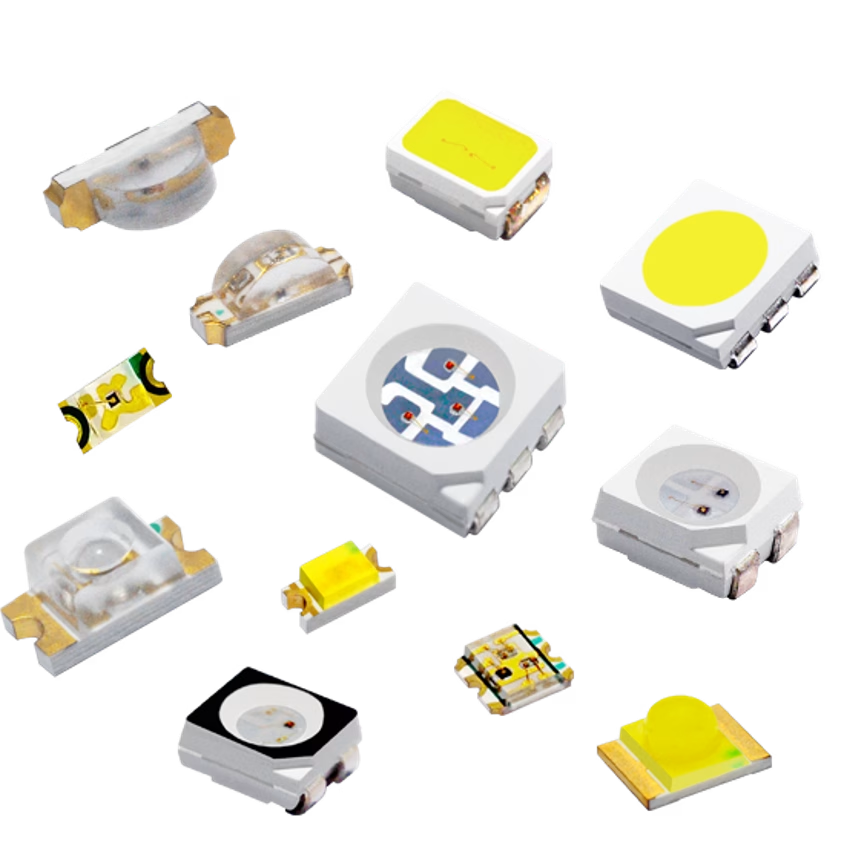

What is the first thing that springs to mind when you think of the LED industry? The solution lies in SMD LEDs. SMD LEDs are now a fundamental component of optoelectronics, particularly those with built-in ICs. Numerous consumer electronics, automobiles, and industrial displays employ this technology.

1.What is An SMD LED with Built-in IC?

An SMD LED with a built-in IC is a tiny optoelectronic component. Surface-mount chip packages integrate an LED with a driver/control IC. Surface mount technology, which is used for a three-in-one design, allows the chip to be soldered directly onto the PCB. This design combines electronic drive, intelligent controls, and light emission into a single structure.

2.The Conventional Design of An SMD LED with Built-in IC

2.1 Light-emitting layer

This LED chip combines a YAG-phosphor with a GaN-blue LED chip. It emits white light, which typically has a color temperature range of 2700K to 6500K.

2.2 Control layer

Driver ICs have integrated circuitry. These include a constant-current source, a dimming module with PWM, and a protocol decoder. Signal processing is usually done by the decoder using SPI/I2C/single wire interfaces.

Three layers of protection are also included in the integrated circuitry: thermal shutdown, thermal overcurrent and overvoltage. To safeguard the circuit, they’re automatically triggered when specific criteria are crossed.

2.3 Packaging Structure

Substrate material:Good-temperature co-fired ceramic and epoxy resin with good thermal conductivity are typically used as the lamp bead’s substrate materials.

The microlens array is integrated into the lamp bead. The lamp beam angle is 120deg+-10%. The uniformity of the light is greater than 90%.

This table compares SMD LEDs with built-in ICs to SMD LEDs with external ICs.

| Comparison Aspect | SMD LED with built-in IC | SMD LED with External IC | |

| Reliability & Maintenance | Electromagnetic Interference (EMI) | Hermetic better resistance packaging shields (internal circuits). | Without proper shielding, you are more vulnerable to EMI. |

| Failure Handling | If the IC fails, you must replace the entire LED module. | Replace ICs that have failed. Reduce repair costs individually. | |

| Functional Performance | Control Flexibility | Fixed functionality with pre-programmed features (e.g. dimming). | Flexible programming via external drivers. |

| Heat Dissipation | Advanced thermal design is required to deal with the heat generated by LED/IC. | Heat is distributed across the PCB with simpler thermal management. | |

| Power Efficiency | Energy loss can be reduced by reducing the length of signal paths; power management is optimized. | Power consumption may be increased by longer traces or separate drivers. | |

| Cost & Manufacturing | Assembly Cost | Reduced (fewer components on PCB). | Increased (higher soldering for separate ICs). |

| R&D & Component Cost | Integrated packaging increases initial R&D costs. | Lower component cost (standard off-the-shelf drivers and LED). | |

| Structural Design | Physical Form | Monolithic structure: a single package that performs both functions. | More PCB space is required for discrete components. |

| The integration of technology | LED chip and IC control are packaged in a single integrated chip. | The IC and LED chip are separate components on the PCB. |

3.Benefits of An SMD LED with a Built-in IC

3.1Reliability

SMD LEDs with built-in ICs can be packaged at the chip level. You can’t go wrong. Intermetallic compounds (IMCs) can cause degradation of the polymer insulating layer of LEDs. Solder joints and lead aging can cause problems.

3.2 Response speed

The SMD LEDs that have built-in ICs provide chip-level precision. The dimming time is less than 100 nanoseconds. Conversely, traditional LEDs operate more slowly. External drivers cause delays due to signal conversion and PCB trace parasites.

3.3 Production Yield

The SMT process (Surface Mount Technology), which is fully automated, allows for the production of SMD LEDs that have built-in ICs. The production yield is greater than 99.5%. The IPC-A 610 Class 3 standard for quality and reliability is met.

Most traditional LED products are manufactured using an automated reflow process. The production yield is only 92% because of the intrinsic constraints of temperature controls and component alignment accuracy.

The SMD LEDs with built-in ICs are more reliable than traditional LED assemblies and can be automated.

3.4 Control Accuracy

Traditional LEDs are dimmed with +-10% accuracy using analog methods. SMD LEDs that have built-in ICs provide 16-bit digital precision.

3.5 Development Cycle

The development cycle is significantly shortened by SMD LEDs that have built-in ICs. Plug-and-play configuration is possible in just one or two days. However, it takes 6-8 weeks to develop traditional LEDs.This is due in large part to the IEC 62304 certification for medical-grade systems.

3.6 Circuit Complexity

Direct surface mounting SMD LEDs with built-in ICs eliminates any external components. There is a 45% decrease in the BOM. Conventional LED configurations require independent driver circuits, which occupy more than 30% of the printed circuit board. The board area is reduced by 68% when compared with discrete solutions.

common types of smd led with built-in ic

4.Different types of an SMD LED with Built-in IC

4.1 Classification based on Size and Form Factor

This table shows the most common SMD LEDs.

| SMD LED Type | Dimensions | Key Characteristics | Applications |

| 5050 | 5.0 × 5.0 | Higher power (0.2 – 0.5W) and high brightness | Used for RGB backlit displays, light strips, and decorative lighting. |

| 4020 | 4.0 × 2.0 | Balanced in size and brightness, with the power of 0.3 – 0.8W | Great for outdoor lighting, signboards, and commercial displays. |

| 3535 | 3.5 × 3.5 | Higher power (0.5 – 1.5W) | Applied in high-brightness lighting, car headlights and industrial lighting equipment. |

| 3528 | 3.5 × 2.8 | Low to medium power (0.06 – 0.2W) | Suitable for LED strips, general lighting, and LCD backlighting purposes. |

| 3030 | 3.0 × 3.0 | High power (1.0 – 3.0W) with high lumen output | For plant growth lamps, smart lighting, and high-performance commercial lighting fixtures. |

| 2835 | 2.8 × 3.5 | Compact but with higher power (0.2 – 0.5W) | Used in downlights, LED panels, and high-brightness light strips. |

| 0603 | 0.6 × 0.3 | Low power, consuming 0.02 – 0.06W | Ideal for wearables, smartphones and small-sized electronic devices. |

4.2 Classification of Color Capabilities

(1)RGB:

An LED that combines red, green, and blue to create over 16 million different light hues is known as an RGB LED.

(2)RGBW:

The RGBW LEDs are made up of four chips: red, green and blue. RGBW LEDs are able to produce an endless number of colors when they mix the light from different chips in different ratios.

(3)Tunable White:

With tunable white, you can adjust the color temperature. This technology allows you to alter a light’s color temperature at any moment.

(4)Single Color:

Monochrome LEDs cannot mix colors, unlike RGB or multicolor LEDs. They emit only one color like red, blue, or green.

4.3 Classification based on Drive Current Specifications

(1)High-Current (200mA-1A):

The SMD LEDs that have high currents are available in a range of voltages between 24 and 48V DC. Multi-chip packages are available. The high current generates heat. A strong thermal management system will ensure reliability and long-term service.

(2)Mid-Current (50-150mA):

The SMD LEDs that have medium current are available in a voltage range of 12-24V DC. Dimming is done using integrated PWM. This is a combination of brightness, energy efficiency, and light efficiency. This is the most common indoor lighting, both for decorative and general lighting.

(3)Low-Current (5-20mA):

The voltage range for low-current SMDs is between 3-5VDC. Packaging is a miniature COB/CSP. The luminous intensity is low, but sufficient to carry out the basic functions. Perfect for situations where stringent energy saving and low power consumption are required.

4.4 Classification based on the Direction of Light Emission:

(1)Front Emission:

The front surface is used to attach the LED lamp beads to the PCB. The board is at a straight angle to the light. This design provides a viewing angle of approximately 140deg to 160deg around the board.

(2)Side Emission:

The edge of the PCB is fitted with lamp beads. The light is emitted parallel to the PCB from its sides. The light can be redirected by components such as light guide plates. The circuit board is blocking a portion of the light beam, so these screens can only be viewed from a certain angle. They are more light-transmitting.

front emission vs side emission

4.5 Classification of Communication Protocols

(1)Single Wire Addressable:

This type of LED can be controlled with a single data cable (e.g., daisy chain configuration).

(2)SPI (Serial Peripheral Interface):

SPI SMD LEDs allow for high-speed communication. SPI SMD LEDs control their timing using independent clocks.

(3)I²C (Inter-Integrated Circuit):

I²C LEDs are LEDs that use the I²C protocol to communicate with circuits. The I²C bus, a two-wire serial port interface, is used to address and control the LED. Examples of popular modules include those driven by the PCA9685.

5.What are the core functions of an SMD LED with Built-in IC?

5.1 High-Density Displays

The ultra-compact packaging and integrated driver ICs of these LEDs make them stand out. Pixel pitch of P0.4 can be attained with these LEDs. For displays with great resolution, this is perfect.

5.2 Dynamic Lighting Effects

16.7 million distinct colors can be produced with RGB color-mixing integrated circuits. In less than one millisecond, the ICs respond. This makes color transitions fluid.

5.3 Environment Adaptability

The ambient light levels can also be detected by them. The brightness of the LEDs can be adjusted automatically by them based on ambient lighting levels.

5.4 External driver free Operation

These SMD LEDs are equipped with constant-current ICs. This LED can be directly powered by 3-5V power supplies. This setup eliminates external driver circuits.

6.The Applications of An SMD LED with Built-in IC

6.1 Industry IoT

SMD LEDs equipped with high-intensity and strobe ICs. These are great for quickly identifying items on conveyor belts. Many factory automation systems use these sensors. WiFi/Bluetooth can be found on smart switches and bulbs with embedded ICs. Users can adjust brightness and color with apps. In vertical farming, SMD LEDs are used with a spectrum-tuning chip to increase plant growth. To increase photosynthesis, for example, planters can change the proportion of red to blue light.

6.2 Aviation & Aerospace

Radiation-hardened SMD LEDs with built-in ICs are utilized in airplane instrument panels. It can be utilized to offer dependability in challenging circumstances like radiation and high temperatures. Low-power SMD LEDs can be used as cabin signs and for escape route markers. These LEDs are designed to run continuously and have fail-safe ICs.

6.3 Consumer Electronics

The built-in IC allows SMD LEDs to dim dynamically. Additionally, this enables accurate local dimming and consistent brightness. It is used by wearables, smart devices, and appliances like televisions.

6.4 Medical & Healthcare

Flicker-free illumination is produced by combining these SMD LEDs with constant-current integrated circuits. They are therefore ideal for cameras and surgical lights. They are used with light sensors in medical devices. They are able to measure heart rate and blood oxygen levels precisely. It ensures accurate monitoring of health.

6.5 Automotive & Transportation

SMD LEDs with built-in ICs have low power consumption and can produce multi-color effects. The LEDs are able to create dynamic signals and flowing effects. Better visual effects are also produced by high-density SMD LEDs. Instrument panel displays and exterior and interior lights are two applications for this kind of LED.

6.6 Commercial & Architectural Lighting

Color mixing ICs are a feature of these SMD RGB/RGBW LEDs. These LEDs can be used for storefront signage and eye-catching signs. Any atmosphere may be produced with them. Museums and jewelry stores employ SMD LEDs with constant-current ICs. These LEDs can be used to highlight your product without damaging it with heat.

7.Manufacturers of SMD LED with Built-inIC

There are many SMD LEDs that with (Built-in) IC manufacturers. This list includes the most representative manufacturers.

Sanan Optoelectronics (China)

Jufei Optoelectronics (China)

HC SemiTek (China)

Seoul Semiconductor

Worldsemi (China)

AMS OSRAM

Samsung LED

BOE (China)

Lumileds

Nichia

…

8.FAQs about SMD LEDs with Built-in IC

1) Can SMD LEDs with built-in ICs be cut?

No. You can cut SMD LED strips with built-in ICs safely at marked intervals. Modular units and products that are encapsulated in a special way cannot be cut. We can’t damage the internal circuits or invalidate certifications.

2) Why does an SMD LED flash with a built-in IC?

This can be caused by a number of factors. It can be due to faulty drivers or loose connection. This could be caused by incompatible dimmers, problems with internal circuitry or thermal management.

3) How long will an SMD LED last with a built-in IC?

With proper thermal management, electrical engineering and environmental protection, these LEDs can last from 50,000 hours to 100,000.

4) Can SMD LEDs with built-in ICs be recycled?

Yes. LEDs that have electronic components integrated into them are more difficult to recycle than standard LEDs.

5) Why doesn’t an SMD LED with a built-in IC light up?

It can be due to a variety of reasons. This can be caused by a number of issues.

6) What is the purpose of SMD LEDs with built-in ICs?

Operation begins with power input. The IC processes and regulates signals in order to make the LED emit a glow. The power source powers the system. The IC controls the lighting parameters based on input signals. It can produce different results.

7) What are the uses of SMD LEDs that have built-in ICs in them?

SMD LEDs with built-in ICs can be used in many situations. All of these require high reliability, precision control and miniaturization. Examples include medical devices, sensor fusion modules, and tunable-white-light lighting systems.

8) How do you select the right SMD LED with a built-in IC when it is?

Along with package size, climatic circumstances, and reliability criteria, other crucial factors include lighting needs, electrical specifications, and control interfaces.

9.Summary

Chip-level integration of SMD LEDs with built-in ICs is accomplished. The system combines sophisticated control, drive, and closed-loop power delivery in a compact design. This innovation will transform the state-of-the-art in contemporary technology. Please wait and see.

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto

Latest Blog

Table Of Contents

Contact Us

Phone: +86-18123905375

Email: [email protected]

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Free Queto