Circular Cable Assemblies

Circular Cable Assemblies are a special type of cable assembly in the field of electronic interconnection, designed for harsh environments and complex scenarios.

1. What are the Structural Design of Circular Cable Assemblies?

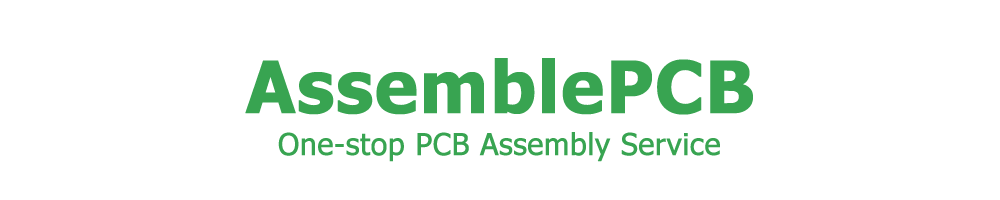

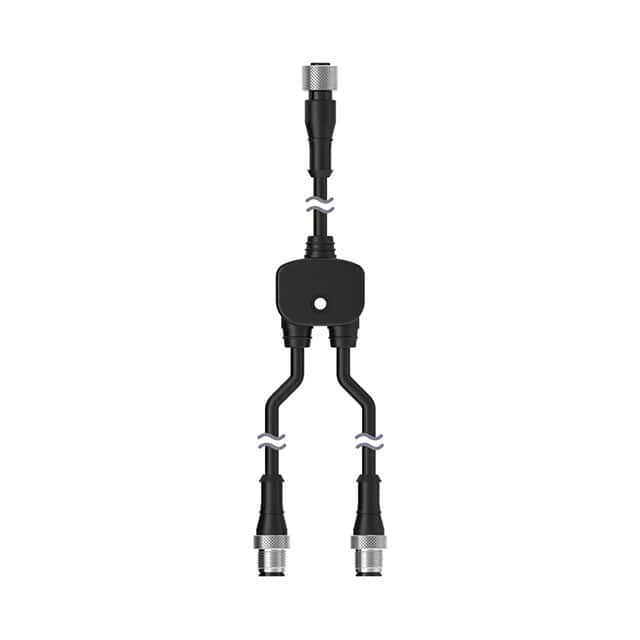

The circular connector shell supports high-density contact arrangement, especially in miniaturized design, it can still maintain the stability of multi-pin configuration.

The connector gender (male/female) is decoupled from the shell gender, with high design flexibility to meet customized needs.

The cable diameter covers 0-26 AWG, which is suitable for different current and signal transmission needs.

2. What are Circular Cable Assemblies Used for?

Military and Shipbuilding: Certified by MIL standards, resistant to extreme temperatures, vibration, humidity, and electromagnetic interference, suitable for shipborne equipment, field communications, and other scenarios.

Industrial Equipment: Used for signal and power transmission with high-reliability requirements such as factory automation and robot control.

Aerospace: Meet the needs of lightweight, radiation resistance, and high sealing.

3. What are the Advantages of Circular Cable Assemblies?

Withstand Voltage and Durability: Package size and material selection directly affect to withstand voltage levels, and large packages can support higher voltage environments.

Signal Integrity: Reduce signal attenuation and crosstalk through shielding design and high-quality insulation materials (such as nylon and metal oxide film).

Fast Deployment: Modular design supports plug-and-play and reduces the complexity of on-site installation.

4. Typical Manufacturers of Circular Cable Assemblies

Electro Standards: Provides MIL standard circular custom cable assemblies that support multi-pin arrangement and miniaturized design.

Molex: Produces high-density interconnect solutions such as Mini-LC fiber optic assemblies to meet the needs of miniaturized equipment.

5. How to Choose Circular Cable Assemblies?

Choose products that meet IP ratings or MIL certifications based on the working environment (temperature, humidity, vibration).

In high-density scenarios, parameters such as pin spacing and contact resistance are prioritized to ensure long-term stability.

Such components play a key role in complex system integration and require balancing performance, cost, and reliability based on specific scenarios.