Explore the SDM10M45SD-7-F, a high-performance Schottky diode array from Diodes Incorporated, perfect for advanced circuit designs and power management. In the intricate world of electronics, every electronic component plays a pivotal role in ensuring optimal performance, efficiency, and reliability. Among these, discrete semiconductor products [...]

1. Introduction: The Unsung Hero of Electronics In the vast and intricate world of modern electronics, every component plays a crucial role in ensuring the seamless operation of devices and systems. From consumer gadgets to heavy industrial machinery, the reliability of [...]

DH-37-CMB(8.8) from Hirose is a prime example of a meticulously engineered D-shaped connector cable clamp designed for high reliability and demanding devices.

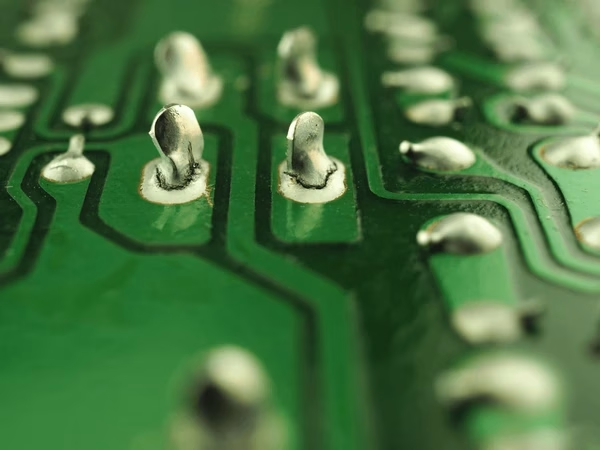

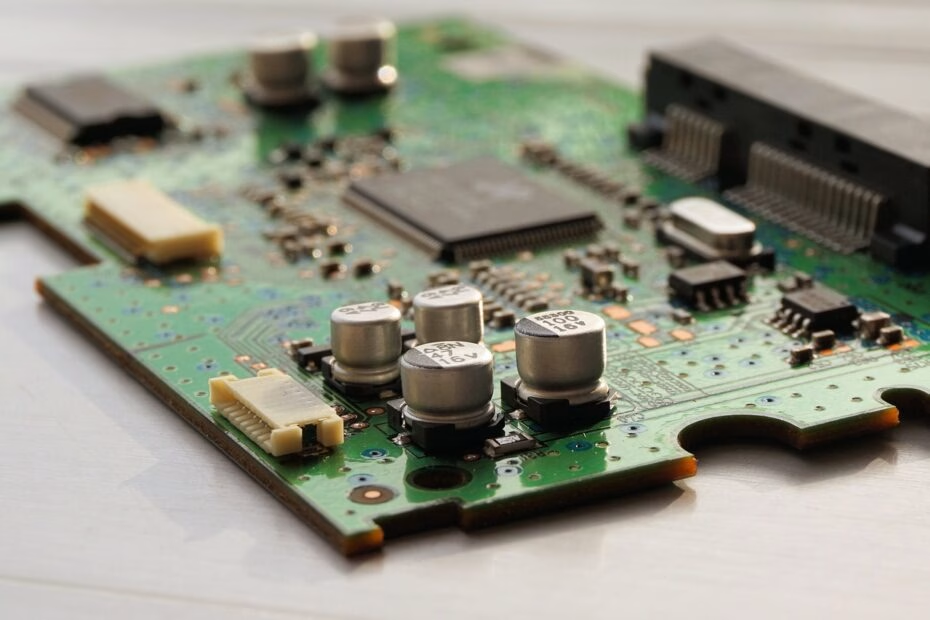

Introduction Cold solder joints are also known as pseudo-soldering. They are a bad solder joint that is produced during PCBA or SMT. The solder joint is unreliable because it lacks good intermetallic compound (IMC) formation. This can cause serious line failures. [...]

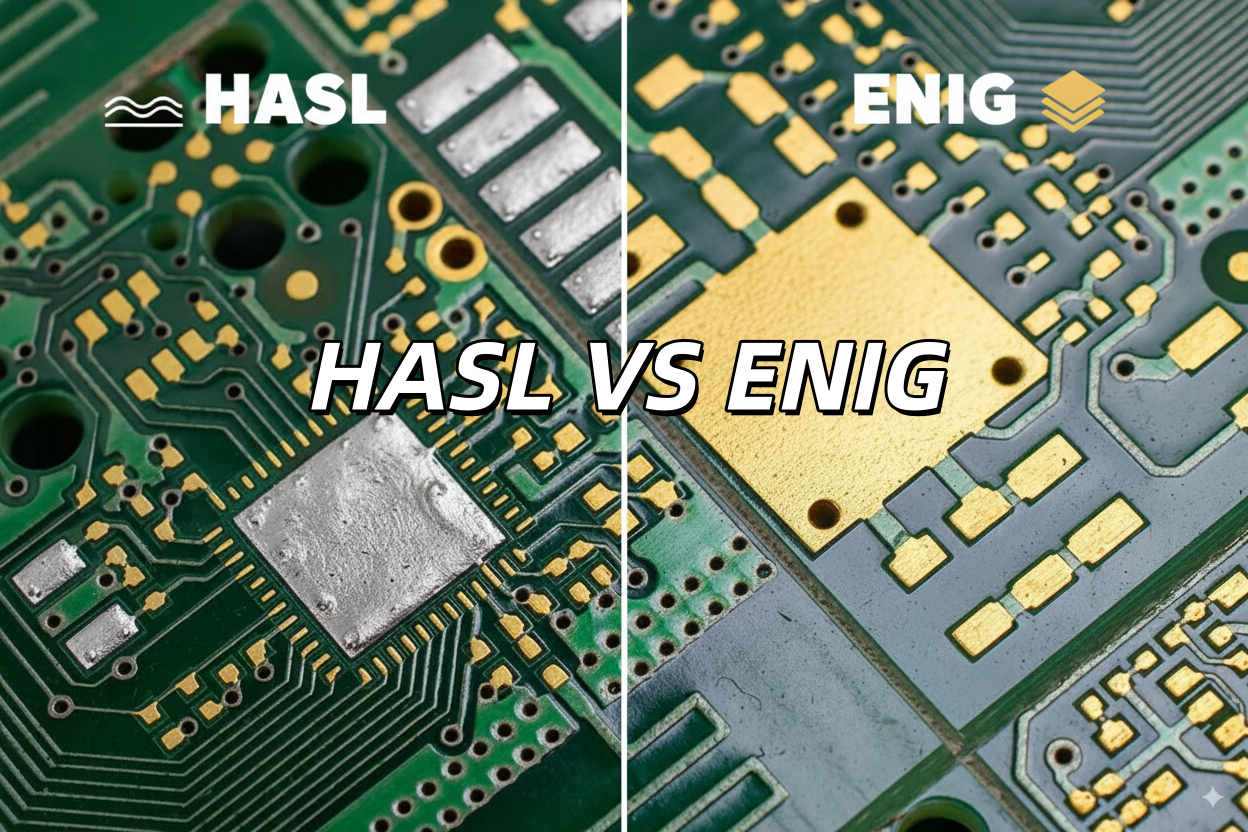

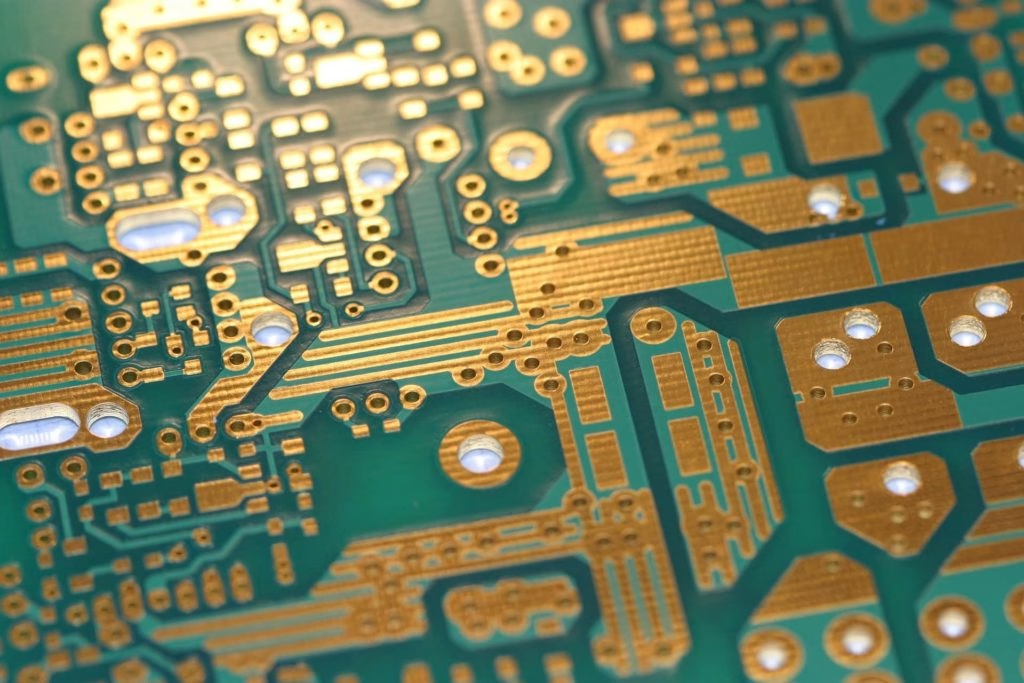

Introduction Surface finishes are crucial in PCB production. They guarantee peak performance and shield exposed copper traces. These finishes are a barrier to oxidation, and they facilitate soldering connections that are reliable. They have a direct impact on the longevity [...]

1. What is Copper Clad Laminate? Copper Clad Laminate (abbreviated CCL) is a base material for PCBs. A copper-clad panel is made by laminating glass fiber or wood paper with copper on one or both sides after the material has [...]

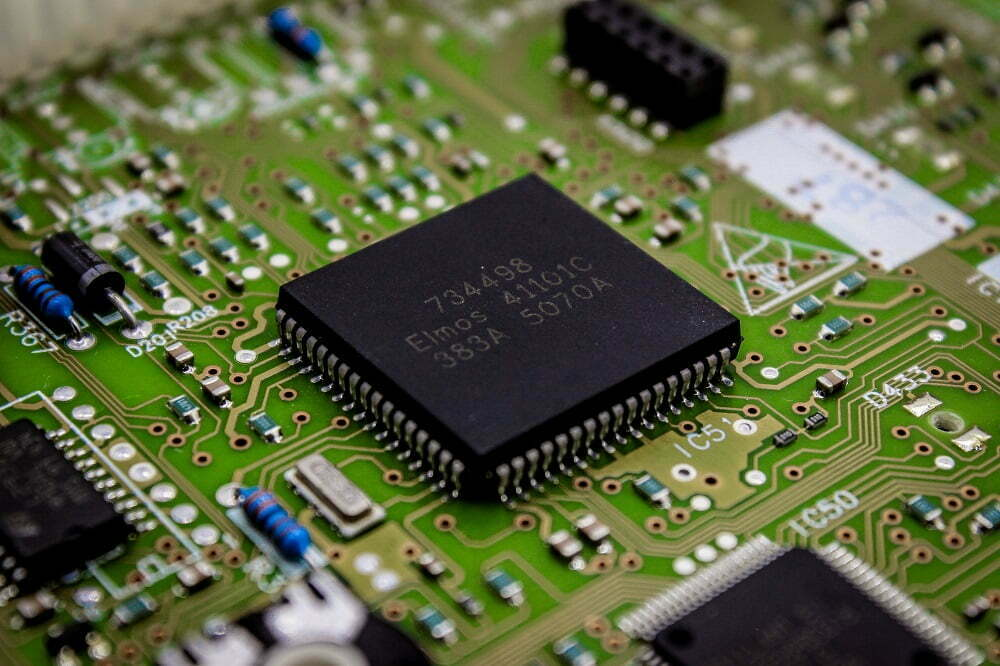

An essential component of the electronics industry is Surface Mount Devices (SMD). Miniaturized circuits, sleeker designs, and improved performance have all been made possible by these tiny gadgets. Understanding SMD components is crucial for understanding how electronic circuits function if [...]

Through precise circuit design and component integration, PCBA (Printed Circuit Board Assembly), the "nerve center" of electronic devices, makes signal processing, power distribution, and functional control possible. Numerous procedural and technical difficulties in its process have an immediate effect on [...]

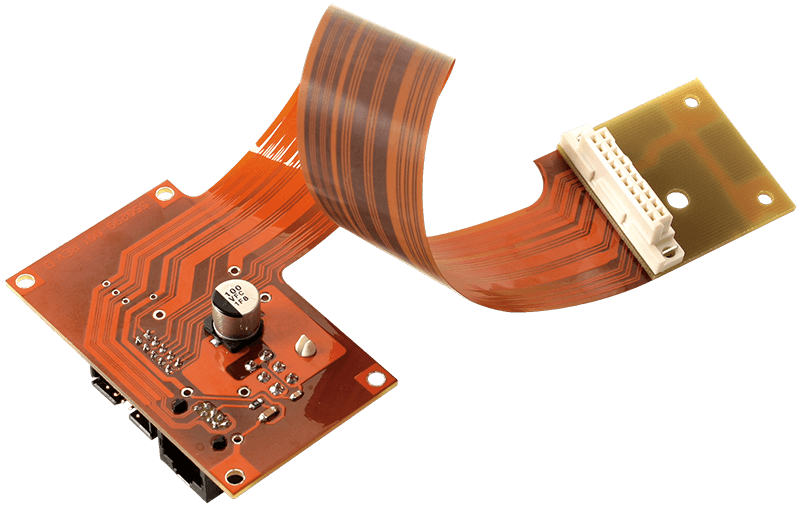

Can a printed circuit board be bent freely? Yes, but only in the case of flexible PCBs. You may wonder what the benefits of flexible PCBs are. Because they can adapt to any device with curved shapes, they provide unparalleled [...]

Printed Circuit Board Assembly (PCBA) is attaching electronic components to a PCB to form a functional circuit, combining precision engineering, automation, and strict quality control.

Blog Category